Nasz łotewski partner dystrybucyjny Elektrodi od 27 do 29 listopada brał udział w największych targach przemysłowych w krajach bałtyckich – Tech Industry 2025 w Rydze. Byliśmy tam razem z nimi, aktywnie wspierając organizację stoiska oraz prezentację najbardziej zaawansowanych rozwiązań spawalniczych z naszej oferty.

Read more ... W dniach 14-16 października 2025 będziemy brać udział w Międzynarodowych Targach Spawalniczych ExpoWelding w Katowicach

W dniach 14-16 października 2025 będziemy brać udział w Międzynarodowych Targach Spawalniczych ExpoWelding w Katowicach

Z przyjemnością informujemy o rozszerzeniu naszego asortymentu o AeroGuard – nowoczesny system monitorowania jakości powietrza stworzony przez firmę Plymovent. To kompaktowe, zaawansowane technologicznie urządzenie pozwala na bieżąco kontrolować jakość powietrza w pomieszczeniach przemysłowych, biurowych i komercyjnych, zapewniając bezpieczeństwo i komfort pracy.

Read more ...

Under GOLD brand you can find many high quality welding consumables.

Read more ...

Our own brand, designed especially for welding industry. High quality for reasonable prcies.

Read more ...We are a producer of high quality welding consumables and abrasive materials at reasonable price. We also own a bandsaws blades welding manufactury.

Please feel free to contact us.

Approvals: MOST SG2 ITS TÜV, DB, GL, DNV, PRS MOST SG3 ITM TÜV, DB, DNV, PRS

Offer: Bandsaw blades of various parameters for all kinds of band saws.

Offer: Abrasive materials of all kinds and destination.

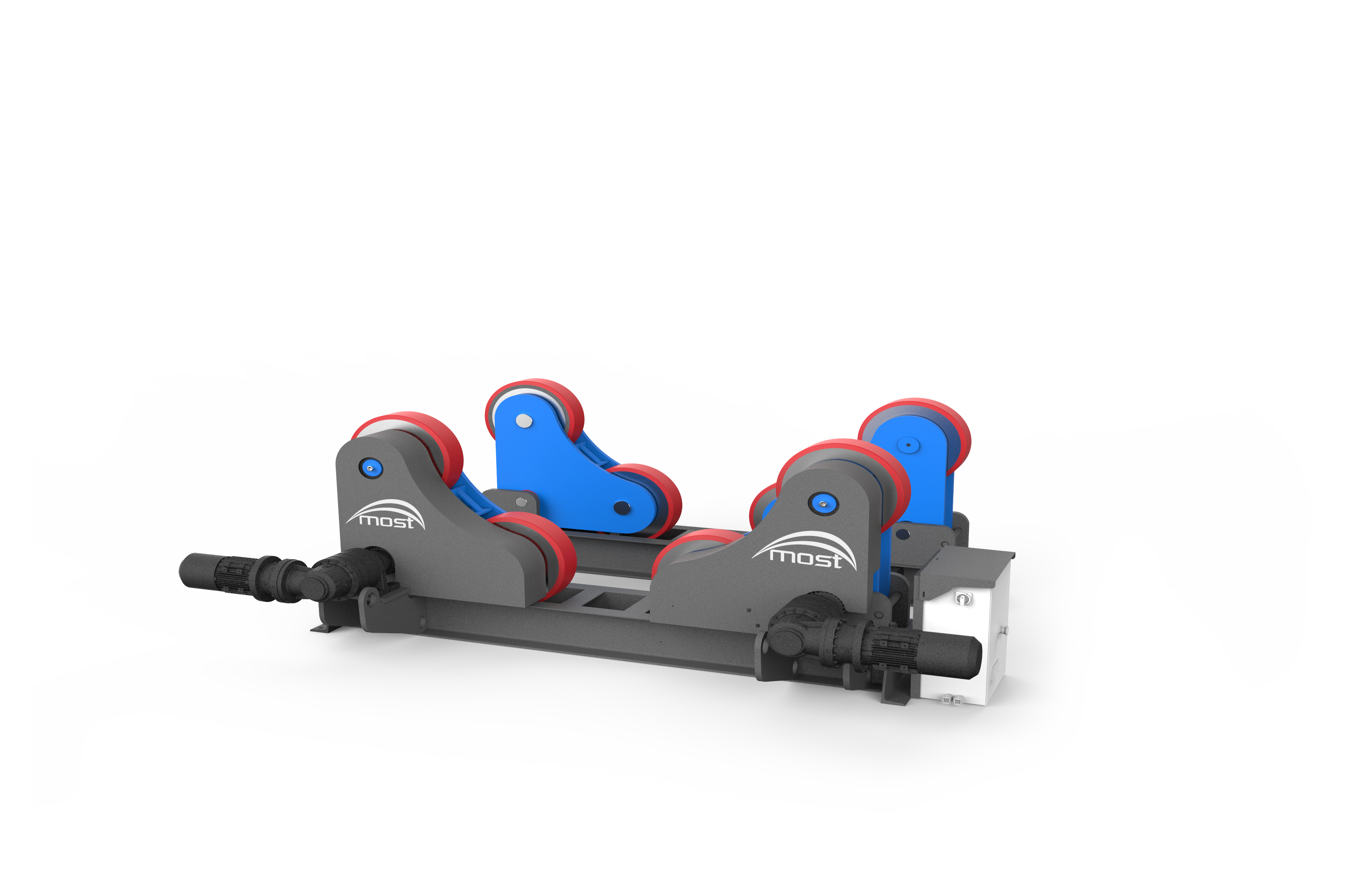

Turning rolls are designed to support tanks, large diameter pipes and any other type of cylindrical objects. These units provide a wide array of compatible work-pieces and precise adjustments as needed, what reduce preparation time and allow the operator to manipulate work-pieces to the optimal position.

Self-align rotators series MOST MSR are perfect solution for the manipulation of thin-walled work-pieces, heavy and difficult objects. These units enable equal loading, constant rotation speed and quick adjustment to accommodate a wide range of work-piece diameters (no other adjustments required). Capacities range from 5 to 200 tons and 250-7000 mm diameter range

Standard features:

Optional features:

|

Model |

MSR-03 |

MSR-05 |

MSR-10 |

MSR-20 |

MSR-30 |

MSR-40 |

MSR-50 |

MSR-60 |

MSR-80 |

MSR-100 |

MSR-150 |

MSR-200 |

|

|

Capacity [t] |

3 |

5 |

10 |

20 |

30 |

40 |

50 |

60 |

80 |

100 |

150 |

200 |

|

|

Load capacity [t] |

1,5 |

2,5 |

5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

75 |

100 |

|

| Rotation speed [mm/min] | 125-1250 | 125-1250 | 125-1250 | 125-1250 | 125-1250 | 125-1250 | 125-1250 | 125-1250 | 125-1250 | 125-1250 | 125-1250 | ||

|

Min. diameter [mm] |

d |

250 |

250 |

450 |

450 |

450 |

520 |

520 |

520 |

520 |

600 |

600 |

1000 |

|

Max. diameter [mm] |

D2 |

2200 |

3000 |

3000 |

4600 |

4600 |

5200 |

5200 |

5200 |

5500 |

6000 |

6000 |

7000 |

|

Roller diameter [Ø mm] |

RD |

220 |

250 |

350 |

375 |

440 |

440 |

440 |

550 |

550 |

550 |

550 |

650 |

|

Roller width [mm] |

RW |

75 |

75 |

100 |

125 |

125 |

125 |

150 |

130 |

175 |

260 |

310 |

360 |

|

Roller material [mm] |

PU |

PU |

PU |

PU |

PU |

PU |

PU |

PU |

PU |

PU |

S |

S |

|

|

Overall length - idler [mm] |

L1 |

1180 |

1180 |

2000 |

2020 |

2100 |

2120 |

2120 |

2780 |

2780 |

2900 |

3020 |

3300 |

|

Overall length – drive [mm] |

W1 |

465 |

465 |

550 |

660 |

670 |

680 |

705 |

705 |

850 |

900 |

1200 |

1250 |

|

Overall width - drive [mm] |

L2 |

1480 |

1480 |

2600 |

2685 |

3100 |

3200 |

3200 |

3750 |

3750 |

4400 |

4500 |

4850 |

|

Overall width – idler [mm] |

W2 |

530 |

530 |

730 |

785 |

900 |

900 |

925 |

1000 |

1200 |

1250 |

1650 |

1700 |

|

Height over roller [mm] |

H |

505 |

515 |

930 |

950 |

1010 |

1050 |

1050 |

1310 |

1310 |

1310 |

1385 |

1415 |

|

Motor power [kW] |

1x0,37 |

1x0,37 |

2x0,37 |

2x0,37 |

2x0,55 |

2x0,75 |

2x1,1 |

2x1,1 |

2x1,1 |

2x1,5 |

2x3 |

2x4 |

|

|

Weight [kg] |

400 |

400 |

1700 |

1900 |

2700 |

2900 |

3200 |

4000 |

5000 |

6250 |

7450 |

9100 |

|

| *PU = Polyurethane ; S = Steel | |||||||||||||