Laser welding, what is it and how to work efficiently and safely with lasers?

In the following article, we will help you answer the questions about laser welding, which in fact will come down to explaining 3 key areas that should be recognized when implementing laser devices in your company, i.e. issues regarding the laser itself, its selection and possibilities, issues regarding the laser working environment and risk assessment and issues related to the awareness of operators and other workers exposed to possible contact with the laser beam.

What is the laser welding process and why is it gaining popularity?

Laser welding is a modern welding method that is gaining more and more popularity and is used in many industries. The laser welding process opens up new possibilities, not only in terms of efficiency (speed and cleanliness of processes and the possibility of their automation, i.e.laser welding with a robot), efficiency (optimization costs and processes), but also in the field of materials, i.e. welding elements of various shapes and thicknesses.

How does laser welding work?

Laser welding allows you to join metals by melting the contact area of the joined elements with the help of a veryhigh-density condensed beam of lightgenerated by the LASER. LASER (Light Amplification by Stimulated Emission of Radiation), gives a very narrow fusion zone, so any deformations do not require further mechanical treatment. The laser welding process is distinguished by high flexibility, a high degree of control and the ability to carry out welding processes in hard-to-reach places. These aspects make laser welding the fastest welding technology.

How do we classify lasers and which ones do we use in welding?

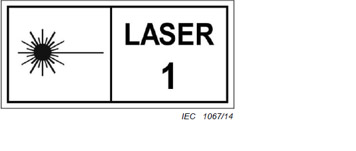

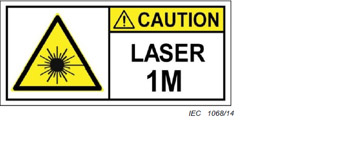

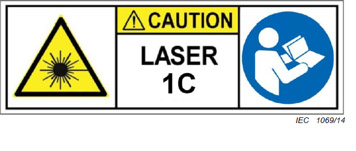

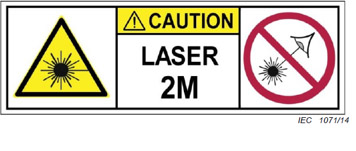

Depending on the laser power, the wavelength of the radiation, and thus the possibility of its application, lasers in accordance with PN-EN 60825-1:2014-11/A11:2021-12 are divided into a total of 7 classes.

|

Class 1 and 1M: Lasers which are safe under reasonably foreseeable conditions of operation. The radiation range: 302,5-4000nm. Class 1M lasers can be dangerous when viewed into the beam through magnifying devices.. |

||

|

Class 1C: These lasers are used in medicine and in cosmetic procedures. The laser only projects the beam when the emitting device (aperture) is in contact with tissue, such as the skin. |

||

|

Class 2 i 2M: Lasers emitting visible radiation in the wavelength range 400-700nm.This laser is completely safe and does not require eye protection in the form of protective glasses or goggles. The eyes are naturally protected by instinctive defence reactions, including the blink reflex. |

||

|

Attention: Class 1M and class 2M laser: devices are special cases of lasers, e.g. lasers with a large beam divergence or collimated lasers with a large beam diameter, for which the work does not pose a high risk, provided that they are used rationally. The only threat is staring into the beam, and staring into the beam through magnifying optical devices, e.g. magnifiers, binoculars, telescopes.. |

|||

|

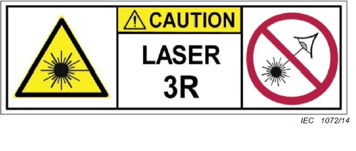

Class 3R: They generate visible and invisible radiation in the wavelength range up to 302.5-106 nm. The risk of eye injury is low, however the laser can be dangerous when viewed directly into the beam or through magnifying devices. There is no risk of skin injuries. |

||

|

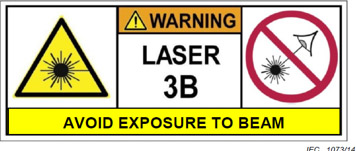

Class 3B: The laser emits visible or invisible radiation. Direct viewing of the laser beams or their observation with optical instruments is prohibited. Viewing the beam is permitted when reflected from the surface, provided that the distance is not less than 13 cm and the viewing time is less than 10 seconds. The use of safety glasses or goggles is required. Lasers with output power close to the upper class 3B can also cause skin burns. Working with this laser class is only possible after successfully completing the health and safety training. |

||

|

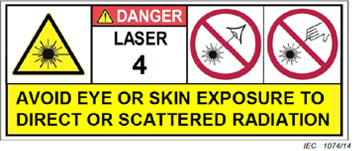

Class 4: Dangerous lasers. Due to the power of the beam, they can produce diffuse reflections, cause damage or carbonization of the skin, risk of blindness and pose a fire hazard. Special care should be taken when working with a class 4 laser, therefore it is recommended to conduct health and safety training on how to use the device by the manufacturer or distributor before starting work with a device of this power. |

||

What lasers are used in industry?

The industry uses high-power lasers, i.e. lasers belonging to class 4. Apart from the division into classes, lasers can also be grouped according to a number of other characteristics, such as the type of resonator, type of work or beam amplifying medium.

The most common types of lasers are ruby, atomic gas (He-Ne), molecular (CO2), ion gas (argon), planar (YAG) and fiber lasers. Apart from them, semiconductor lasers are also used..

What types of lasers are used in laser welding?

Several types of lasers are used for welding:

- Fiber lasers,

- Molecular CO2 lasers with continuous or pulsed emission,

- Laser with an active crystalline element, generating continuous or pulsed radiation (Nd:YAG, Nd: szkło, Nd:YVO4)

- ruby laser, allowing to achieve higher power, where optical pumping is done with a flash lamp,

- semiconductor lasers, electrically pumped, with emission in a wide spectral range from visible to infrared.

| Type of laser beam amplifying medium | Type | Wavelength | Emission |

|---|---|---|---|

| Gas | CO2 | 10.6μm | Continuous or pulsed |

| Solid | YAG (Yttrium aluminium garnet) | 10.6μm | Continuous or pulsed |

| YVO4 (Orthovanadate Yttrium) | 10.6μm | Pulsed | |

| Ruby | 694,3nm | Continuous | |

| Optical fiber | Optical fiber Yb | 980 - 1100nm | Continuous or ultra short Q-Switch pulses |

| Semiconductor | Laser diode | 1070nm | Continuous or pulsed |

How does laser welding work in practice?

The starting beam, passing through the various reinforcing media, goes from the laser to the workpiece and is focused in the welding area. The laser beam hitting the surface of the metal melts it, joining the materials to be welded, and depending on the type of metal and the condition of its surface, it can be reflected.

The effectiveness of laser welding depends mainly on the possibility of absorption of the energy of the laser beam by the surface of the welded element. Therefore, an important activity in laser welding is the appropriate preparation of the surface before welding by roughening or blackening it to minimize reflections and maximize energy absorption by the elements.

When welding thin, less than 3mm thick low-carbon steel sheets, there is no need to protect the weld pool from oxidation, because the process of heating the material and its cooling takes place so quickly that the metal will not oxidize. On the other hand, when welding more reactive materials, it is necessary to use an inert gas shield for the pool and the ridge of the joint.

Laser welding can be done with or without the addition of a binder, which can affect not only the economics of welding, but also the welding efficiency..

The benefits of using lasers in industry

The innovation of laser welding allows you to connect almost all metals and their alloys. The use of laser welding is possible in a wide range of materials such as structural steels, alloy/low-alloy steels, duplex, chemically active metals, refractory metals, aluminium, titanium, nickel, carbon steels and magnesium.

The greatest benefits are obtained when welding thin parts or sheets made of aluminium or alloy metals using manual laser welding.

Laser welding is characterized by many beneficial advantages, such as:

Low heat emission at the station

High thermal power delivered to points, without overheating of the welds

Speed of cooling the weld

High accuracy and speed of welding

Low deformation of the connected elements

High process purity

Possibility and ease of automation

Ability to join materials that are difficult to weld

Ease of welding that does not require special qualifications

High repeatability guaranteeing high quality and aesthetics of elements

Check what benefits can it bring to your company?

What are the safety requirements for working with lasers and laser welding stations?

Welding is an area of industrial processes where the risk of damage to health is very high due to high exposure to harmful factors.

Is laser welding safer than traditional?

Traditional welding methods, due to the welding arc, welding fumes, hot spatter and the risk of electric shock, are harmful factors and are characterized by high risk, which should be minimized using appropriate personal protective equipment and filter ventilation of the workplace, and in the case of third parties, eye protection should be used. Such as curtains or welding screensto protect against accidental exposure to the eyes from the welding arc and minimize the risk of burns from hot spatter.

Modern laser welding changes these hazard characteristics!

Each laser used at the welding station must be properly marked and assigned a class, which requires the use of appropriate personal protective equipment and group protection.

Due to the use of class 4 lasersin welding, a correctly and safely organized laser station requires a detailed assessment of all the risks associated with its operation!

What should the risk assessment include?

Determining the risks for the operator.

Laser welding emits optical radiation in a wide spectrum from UV rays (band below 350nm) to IR rays (band above 1000nm). First of all, it is necessary to minimize the risk of eye damage, the risk of burns, but also the risk of damage to the respiratory tract from welding fumes, especially when welding aluminium and its alloys, and the possible risk of hearing damage.

Determining the threats to the environment both at the welding station and outside it.

First of all, the risk of eye damage to the operator and third parties due to the reflection of the laser beam. The room should be properly marked and secured both against the intrusion of unauthorized persons and against the escape of the reflected beam outside the room.

The level of training of the operator and people in the vicinity of the welding station.

The basic means of individual protection are training and situational awareness of employees.. The proper training system not only for operators but also for people who may be in the vicinity of the laser operation is needed.

Table: Summary of pathological effects of excessive eye exposure to laser radiation

| Wavelength range | The effect of laser radiation |

|---|---|

| Ultraviolet C 100-280nm | Inflammatory damage to the cornea |

| Ultraviolet B 280-315nm | |

| Ultraviolet A 315-400nm | Photochemical cataract, photochemical and thermal damage to the retina. |

| Visible 400-780nm | |

| Infrared A 780-1400nm | Cataract, retinal burn |

| Infrared B 1400-3000nm | Cataract, corneal haze, corneal burn |

| Infrared C 3000nm - 1mm | Corneal burn only |

|

Source: Spectroscopic and resistance characteristics of anti-laser protective filters: Zygmunt Mierczyk, Mirosław Kwaśny, Jadwiga Mierczyk, Jan Kubicki |

|

Table: Basic requirements and recommendations for users of laser devices

| Requirements and recommendations | Laser class | ||||||

|---|---|---|---|---|---|---|---|

| Class 1 | Class 1M | Class 2 | Class 2M | Class 3R | Class 3B | Class 4 | |

| Appointment of a laser safety inspector | +1) | + | + | ||||

| Remote interlock connector | + | + | |||||

| Key control | + | + | |||||

| Beam stop or attenuator | + | + | |||||

| Laser radiation emission warning | +1) | + | + | ||||

| Warning labels | + | + | |||||

| Laser shutters | + | + | + | ||||

| Avoidance of specular reflections | + | + | + | ||||

| Use of eye protection | +2) | +2) | |||||

| Use of protective clothing | +3) | +3) | |||||

| Training employees in the field of safe work with lasers | + | + | + | ||||

|

Source: CIOP.pl |

|||||||

|

1) Only required when radiation is emitted outside the visible range 2) Required if the MPE* values are exceeded in the area of laser radiation exposure 3) Required if laser radiation creates a potential hazard |

|||||||

*The values for maximum permissible exposures (MPE) to optical radiation are set out in Part D of Annex 2."List of the maximum permissible levels of physical factors harmful to health in the work environment" to the Regulation of the Minister of Family, Labor and Social Policy of June 12, 2018 on the maximum permissible concentrations and intensities of factors harmful to health in the work environment.

How to ensure the safety of the operator and third parties during laser welding?

The risk characteristics for laser welding require employers to use a number of personal and collective protection measures as well asoccupational health and safety training. However, it does not differ significantly from the health and safety requirements for a traditional welding station.

What PPE should a welder / laser operator have?

The protection against the laser beam should not be underestimated. The above-mentioned table of the effects of excessive eye exposure to laser radiation does not mean that only the welder's eyes are exposed to damage.Depending on the length of exposure to the laser beam, skin tissue damage and even severe burns can also occur. It is worth approaching individual protection comprehensively.

Eye protection during laser welding

To ensure adequate protection of the operator's eyesight, it is required to provide safety glasses or goggles with lenses equipped with selective attenuating filters.

According to the standard, anti-laser safety glasses should be used by every person working with a laser class 1M, 3R, 3B and 4 (PN-EN 207: 2017-07) or staying in its vicinity.

Attention: Due to the possibility of exposure to the reflected beam, we recommend that you use full eye and face protection in the form of welding helmets with appropriate filters to prevent eye damage due to the laser beam getting into the eye through an unprotected area.

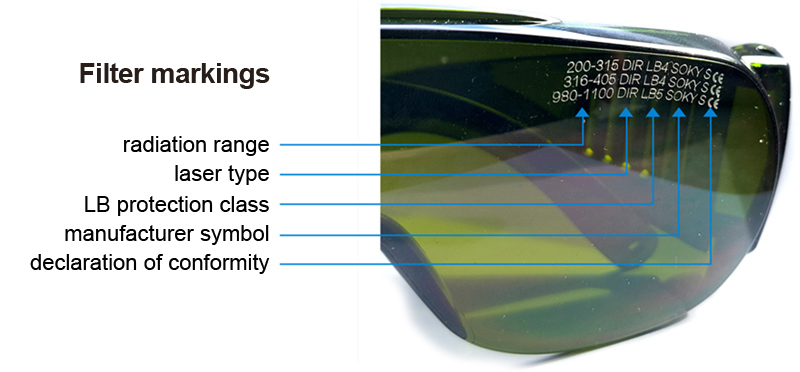

When selecting filters to protect against laser radiation, consider the following:

laser type (D - continuous operation lasers, I - pulse lasers, R - Q-modulated lasers, M - mode-synchronized lasers),

laser wavelength range,

the maximum power or energy density of laser radiation.

How to choose the right laser protective eyewear?

Good laser glasses or goggles should have markings to which radiation ranges, what types of lasers and what degree of protection they guarantee.

To choose the right one, it is best to use the filter selection table, taking into account the laser parameters.

Check the maximum laser beam density (laser power / energy) to determine the necessary LB protection class for the filter, then select glasses or goggles with the appropriate protection class for the indicated laser radiation range.

| Range | Type | LB1 | LB2 | LB3 | LB4 | LB5 | LB6 | LB7 | LB8 | LB9 | LB10 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 180-315nm | D | 0,01 | 0,1 | 1 | 10 | 10^2 | 10^3 | 10^4 | 10^5 | 10^6 | 10^7 |

| I,R | 3x10^2 | 3x10^3 | 3x10^4 | 3x10^5 | 3x10^6 | 3x10^7 | 3x10^8 | 3x10^9 | 3x10^10 | 3x10^11 | |

| M | 3x10^11 | 3x10^12 | 3x10^13 | 3x10^14 | 3x10^15 | 3x10^16 | 3x10^17 | 3x10^18 | 3x10^19 | 3x10^20 | |

| 315-1400nm | D | 10^2 | 10^3 | 10^4 | 10^5 | 10^6 | 10^7 | 10^8 | 10^9 | 10^10 | 10^11 |

| I,R | 0,05 | 0,5 | 5 | 50 | 5x10^2 | 5x10^3 | 5x10^4 | 5x10^6 | 5x10^7 | ||

| M | 1,5x10^-3 | 1,5x10^-2 | 0,15 | 1,5 | 15 | 1,5x10^2 | 1,5x10^3 | 1,5x10^4 | 1,5x10^5 | 1,5x10^6 | |

| 1400nm-1μm | D | 10^4 | 10^5 | 10^6 | 10^7 | 10^8 | 10^9 | 10^10 | 10^11 | 10^12 | 10^13 |

| I,R | 10^3 | 10^4 | 10^5 | 10^6 | 10^7 | 10^8 | 10^9 | 10^10 | 10^11 | 10^12 | |

| M | 10^12 | 10^13 | 10^14 | 10^15 | 10^16 | 10^17 | 10^18 | 10^19 | 10^20 | 10^21 | |

|

Table legend: D - continuous wave (W/m2); I - pulsed laser (J/m2); R - high power pulsed laser (J/m2); M - mod laser (W/m2) |

|||||||||||

Face protection during laser welding

It must not be forgotten that during Class 4 laser welding, not only the operator's / welder's eyes are vulnerable to damage, but also the skin, including the skin of the face. Direct exposure of the laser beam, often invisible to the "naked eye", can carbonize the skin tissue. In order to reduce the risk, use welding masks and welding helmets with a properly selected filter..

Arms and hands protection during laser welding

It is important to provide appropriate protective clothing and accessories made of non-flammable and flexible materials allowing the welder to operate freely and comfortably at the laser welder. The welder must be equipped with certified gloves with a special marking.

Welding gloves, in accordance with the EN 388 standard, must protect the user against mechanical factors, but also protect the hands and wrists against splashes of liquid metal, burns and UV radiation in accordance with the EN 407 standard. The standard introduces a division of gloves according to their protective properties and their dexterity.

Gloves for laser welding are best chosen taking into account the laser power and the parts to be welded.

- Type A welding gloves (MIG / MAG and MMA).Gloves of this type are thicker and adapted to thermal and mechanical protection, although they are less comfortable for manual handling.

- Type B (TIG) welding gloves. Gloves with great comfort, easy and precise grip, thinner but providing basic mechanical, thermal and UV protection.

Protection of the respiratory system

During laser welding, especially when welding aluminum and its alloys, welding fumes harmful to health may be produced. The basis is the proper filtering of the welding station, possibly half-masks with replaceable filters or A2 gas absorbers. However, the best alternative will be to combine eye and face protection with respiratory protection and to use a welding helmet with an appropriate filter and forced air flow..

Hearing protection

Depending on the device and its operating volume, there is a risk of hearing damage. It is recommended, if such a risk exists, to use earplugs, passive earmuffs or active earmuffs to increase employee situational awareness. Permanent damage to nerve cells by noise can have irreversible consequences.

Additional protective clothing

Despite the fact that welders are not exposed to welding spatter, as laser welding is a cleaner process than traditional welding, it is worth providing operators with additional protective clothing such as light, non-flammable welding clothing, i.e. a welding jacket and welding pants, as well as afety footwear with toe cap.

How to properly secure the welding station?

In addition to personal protection, every effort should also be made to adequately protect the environment around the laser welding station and the room in which such welding takes place.

Due to the risk of reflection of the laser beam, the employer must also take into account the safety of third parties. The emission of optical radiation, both ultraviolet (UV), visible (VIS) and infrared (IR), creates a risk for employees not only in the laser room but also outside it. Correct identification of hazards should be the starting point for newly created laser welding stations.

While laser welding equipment can have clearly declared risks, written in the OHS manual for the device, each welding station, each room may differ due to the number of glazing, cubature , the condition of the floor, the way of finishing the walls, entrances and exits from the room.

Therefore, each station and room should be subject to a security audit in order to determine the risk and rules of safety.

Basic safety rules for laser welding workstations and rooms:

The room and workstation should be clearly separated, marked with safety signs and have signalling of the ongoing laser welding process informing about the potential hazard.

Workstation should be equipped with instructions for the safe use of the laser device and health and safety instructions.

Laser welding may only be performed by a trained operator.

Commissioning the laser welder should be secured with a key or other access authorization mechanism.

The room should be finished in a way that minimizes the possibility of reflection of the laser beam, e.g. matte paints, matte glaze or concrete floor, and minimizes the risk of fire.

The room should be equipped with a fire extinguisher or a fire information system.

The room should be properly ventilated, i.e. equipped with an efficient and safe filtering system.

The room should prevent the laser beam from spreading beyond it. All glazing should be protected with curtains or welding screens.

Entrances and exits should also prevent accidental escape of the reflected laser beam outside the room.

The entrances should prevent unauthorized access

Periodic employee training and increasing awareness and responsibility about individual and collective safety.

Consider the need to appoint a laser safety inspector who will audit the safety of the laser welding station, define health and safety rules and supervise compliance with them.

Q&A

In this section, we will try to provide additional answers to the most frequently asked questions about laser welding.

Does laser welding require special qualifications?

In addition to standard welding licenses for selected welding methods, it is necessary to undergo training in the operation of the device and health and safety training for the laser welding station. There are currently no other necessary licenses or certificates for laser welding. There are currently no other necessary licenses or certificates for laser welding.

Which protective helmets work best?

There is no clear answer to this, because the protective helmet should have appropriate filters that provide protection appropriate to the power and range of emission of the laser welder. However, what is crucial for the welding helmet is that it protects the welder from the reflected beam.

Where can you learn to laser weld?

Laser welding is a niche specialty, but you can find welding schools that already offer laser welding training. However, it is worth getting some basic welding qualifications first to better understand the process of joining metals using heat.

Is laser welding safe?

Yes, if we approach it wisely, i.e. use appropriate personal protective equipment and follow the health and safety rules at the workplace.

Contact our export office

Contact us if you would like to receive an offer or learn more about MOST Laser Welding Machines.

Copyright 2023: RYWAL-RHC