Nasz łotewski partner dystrybucyjny Elektrodi od 27 do 29 listopada brał udział w największych targach przemysłowych w krajach bałtyckich – Tech Industry 2025 w Rydze. Byliśmy tam razem z nimi, aktywnie wspierając organizację stoiska oraz prezentację najbardziej zaawansowanych rozwiązań spawalniczych z naszej oferty.

Read more ... W dniach 14-16 października 2025 będziemy brać udział w Międzynarodowych Targach Spawalniczych ExpoWelding w Katowicach

W dniach 14-16 października 2025 będziemy brać udział w Międzynarodowych Targach Spawalniczych ExpoWelding w Katowicach

Z przyjemnością informujemy o rozszerzeniu naszego asortymentu o AeroGuard – nowoczesny system monitorowania jakości powietrza stworzony przez firmę Plymovent. To kompaktowe, zaawansowane technologicznie urządzenie pozwala na bieżąco kontrolować jakość powietrza w pomieszczeniach przemysłowych, biurowych i komercyjnych, zapewniając bezpieczeństwo i komfort pracy.

Read more ...

Under GOLD brand you can find many high quality welding consumables.

Read more ...

Our own brand, designed especially for welding industry. High quality for reasonable prcies.

Read more ...We are a producer of high quality welding consumables and abrasive materials at reasonable price. We also own a bandsaws blades welding manufactury.

Please feel free to contact us.

Approvals: MOST SG2 ITS TÜV, DB, GL, DNV, PRS MOST SG3 ITM TÜV, DB, DNV, PRS

Offer: Bandsaw blades of various parameters for all kinds of band saws.

Offer: Abrasive materials of all kinds and destination.

The product comes with all legally required CE conformity declarations.

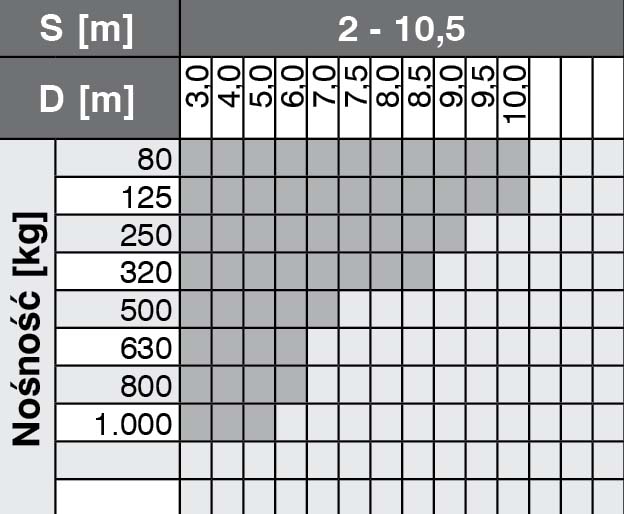

The modular ErgoLine Crane System by Vetter Krantechnik is a lightweight crane system that is a pleasure to move. The cardan suspension for the aluminum beam patented by Vetter Krantechnik allows for uniquely smooth movement, unattainable with other underslung crane systems. The system can be equipped with 400V electric hoists mounted on manually pushed trolleys. Quick delivery times and modularity, allowing you to adjust both the column height and crane span, as well as runway length, mean that in just 6 to 8 weeks your facility can be fitted with a safe, state-of-the-art crane system that will be a showpiece for your company. The ErgoLine system is available in capacities from 80 kg to 1000 kg. Crane span depends on capacity and is up to 5 m at 1000 kg, or up to 10 m at 125 kg.

Machinery Directive 2009/104/EC – Minister of Economy Regulation of October 30, 2002 on the minimum safety and occupational health requirements for the use of machinery by employees at work.

ANNOUNCEMENT of the Minister of Economy, Labor and Social Policy dated August 28, 2003 on the publication of the consolidated text of the regulation of the Minister of Labor and Social Policy on general provisions for health and safety at work.