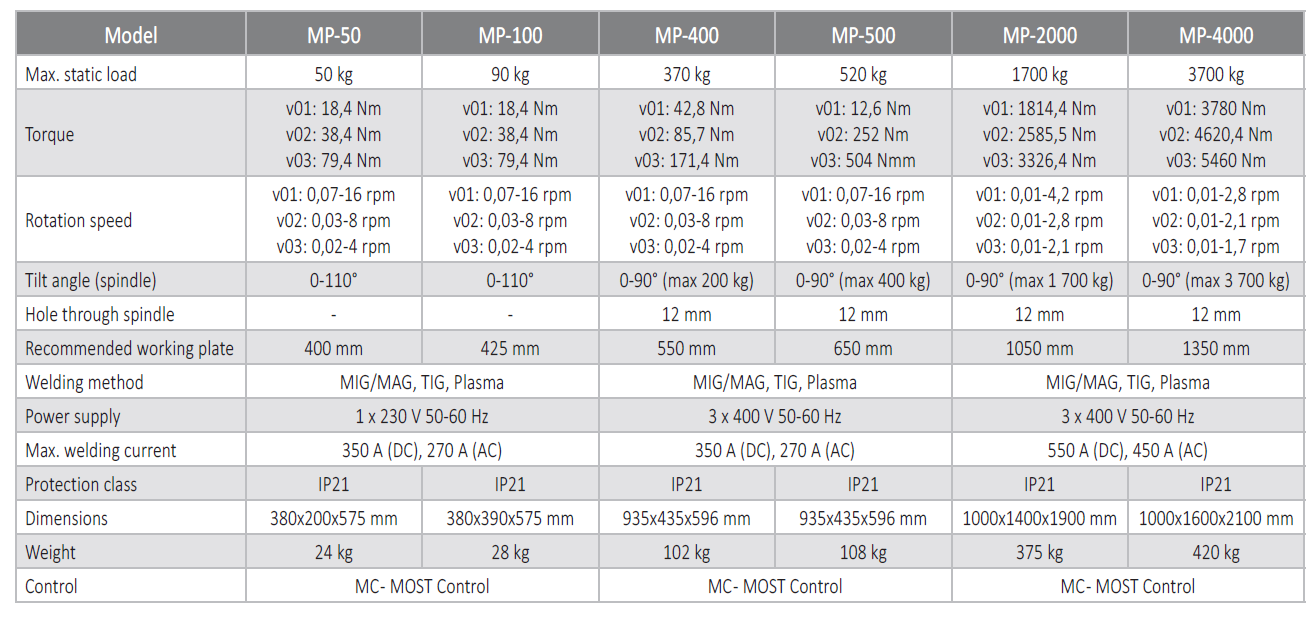

MP is a series of precise automated welding systems, that incorporate high-capacity table-positioners (maximum load capacity up to 3700 kg). This unit features both, simple and reliable construction, and the highest standards of design. The high quality power feeder ensures the stepless and constant rational speed, even in case of the off-axis overloading. The unit can be operated in manual or automatic mode, supported by the high-level automatic functions. With solid, metal construction and spindle interpolated with the unit, it is possible to use operating plate or universal torch. MC control system placed in the main body and metal access door with polycarbonate-glazed viewing window for the protection of control components. Start/stop foot switch pedal to simplify process control, with the precise spindle speed regulation available as an option. Tilt angle range of turntable: 0-110°. The workstation can be equipped with the mounting arm to attach the welding torch, what enables an automatic operation of the positioner. Pneumatic torch slide assembly also

available. The unit can be provided with the integrated shield gas flow system, with a spindle passage through which gas flows.